Hey guys, Rick here from Elijah Tooling.

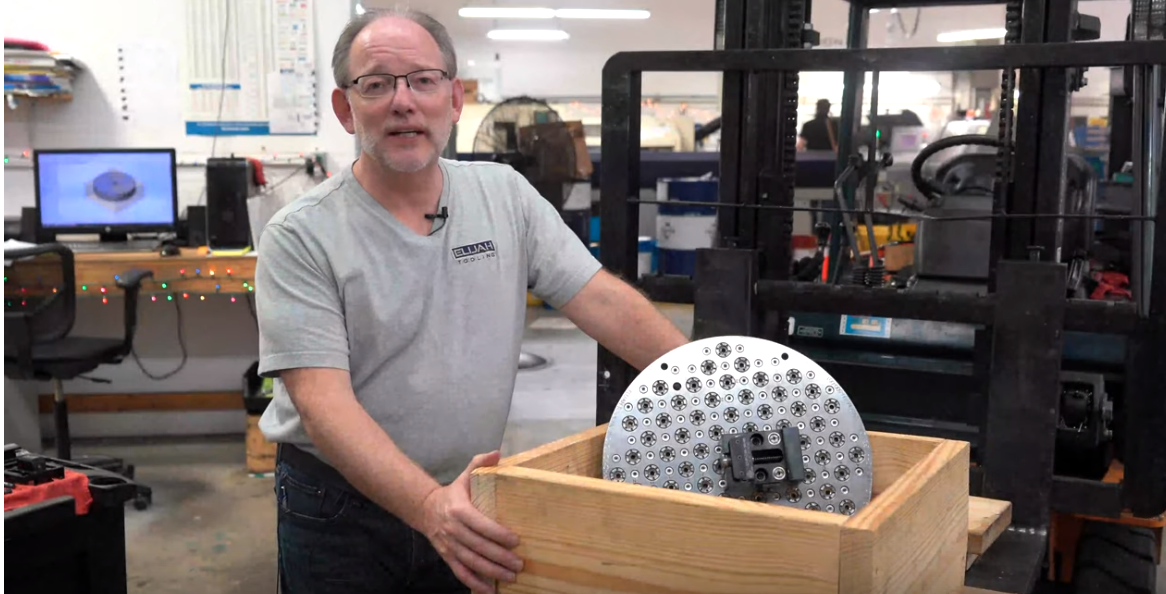

Today, I just wanted to show you these beauties. We are just getting ready to ship them. These are Modular Fixture Plates and I am just going to take a few seconds to describe them so that you know what they do and why you need them.

So, it is a steel plate and it has a standardized pattern. We call this a 2x2 inline pattern which means that the Invert-A-Bolt™ Fasteners are in line with the multi-purpose holes. So, we have a multi-purpose hole here and the fastener here. The multi-purpose hole is used for location and holding.

Right now, we have plugs in this hole but our users would use our Xzertz™ Retractable Locating Dowel Pin. These are pretty cool because they disappear into the plate and you do not have to worry about them being in the way and you can literally raise them up into the piece that is being held.

The other thing, our Invert-A-Bolt™ Fasteners does the same kind of thing; it works, flush mounted in the plate and comes up into the part and hold it. This is why people use these kind of plates. They are able to machine parts without obstruction to the process through workholding.

So, we can hold something with the plate and we do not have to worry about something else running into it and getting in the way. It is a very good use for this type of real estate, if you think about this as real estate, a great efficient use of real estate by use of one of these fixtures.

Those are the two basic elements of the fixture but there are other elements to it as well. One is that you have this scribing that allows you to pinpoint which hole you are using so you can take this and instruct your operator on which location to use, for example, hole 11 and pull it up into the part. That is the idea behind the scribing.

Then, of course, there is some way of locating the plate. In this particular case, we have a center hole that is precision and then we have an alignment edge which is used to align the plate.

There are always going to be these features in these Modular Fixture Plate. you are going to have a pattern, you are going to have these products, you are going to have the scribing, and you are going to have some form of precise location.

We hold, hole-to-hole, about plus and minus half or maybe eight tenths, something like that. That is very close and you can hold just about anything during machining with that kind of precision.

Great to share with you, see you next time!

-Rick

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.