Hey guys, Rick here from Elijah Tooling.

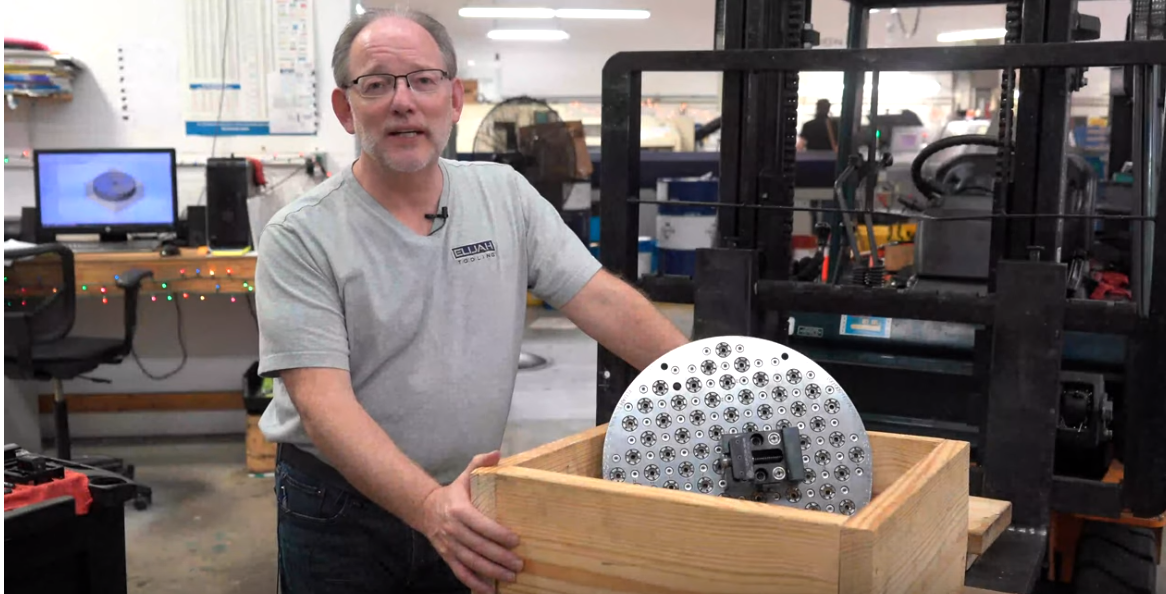

I've got this fixture here that we are going to be sending out to a customer. I thought I would take a few minutes and show you a few things about it. As you can see, I can literally move it around because it is in this box.

This is a round cnc-workholding modular-fixture that is going into an Okuma Trunnion Type 5-Axis machine. And, as you can see, we have set it up with a standard two-inch pattern, just like we have talked about before. It has got the new Invert-A-Bolt Fasteners in it and it has also got the multi-purpose holes. We have talked about them before but, as you can see, it is a bored and threaded hole.

In this case, we are shipping one of our dove-tail vises, the FlexVise with it. But, what I thought was cool and what you should see, is that we have made it so it would adapt to the T-slot fixture that it's going into.

This particular machine has a center plug and we have created a screw-in, precise locating plug that then will locate with respect to a location in the slot.

Here is the other locator. So we have got a locator, another locator, and in between them is the center slot. You can see that we are using our 18-millimeter T-slot Fastener to hold the plate.

This is "kind of" set up the way it is going to look on the machine once it is in the fixture. The T-slot Fastener can come out quite easily and it is in line with the slots and makes for a perfect scenario, in which you have got this fastener that is sitting in this slot and is not moving around. This plate is made specifically for this. You have also got all these locations.

You can see that the threaded holes go all the way through; you do not have to really worry about how deep that screw is going in.

That's about it. We have talked about modular fixture plates before, but I thought this was a beauty, and that we ought to show it to you before it is out the door.

Notice this nice heavy box? That is how they are shipped. It also comes with an inspection port so that you know that this is precisely made and will do the job that you want it to do.

Thank you for your time!

-Rick

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.