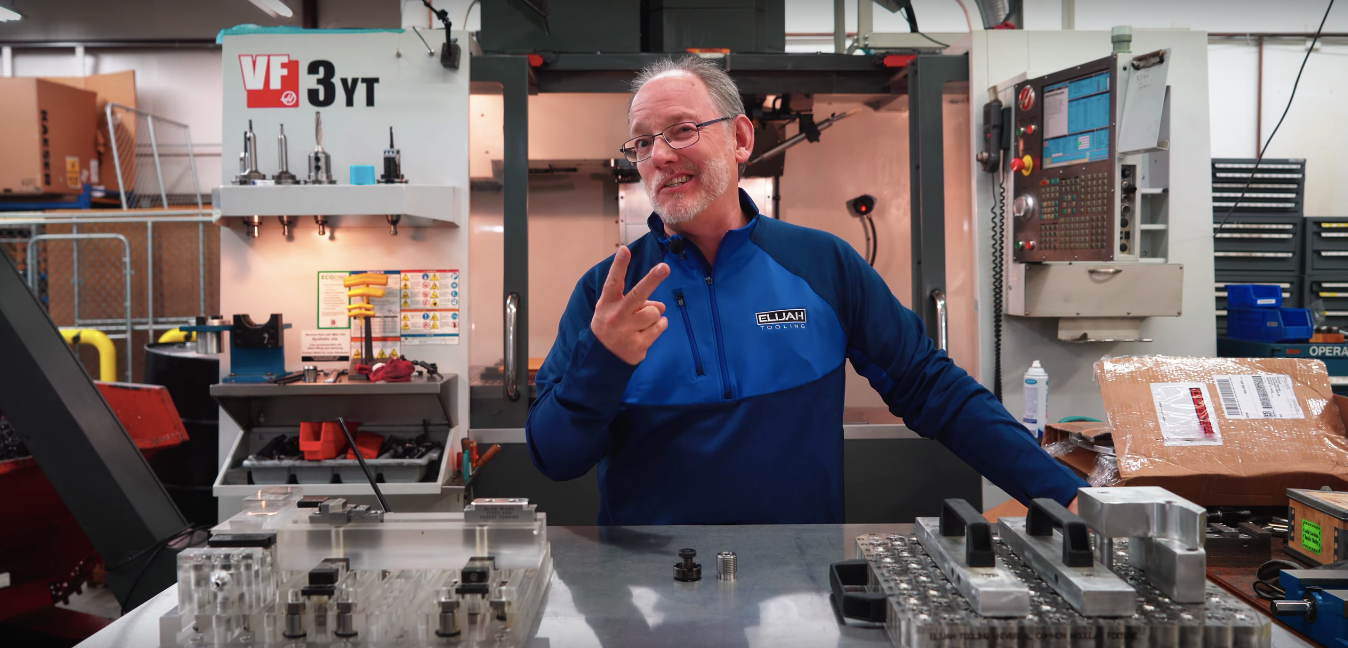

Hey guys, it's Rick from Elijah Tooling, Give me two, I’ll make it worth your while.

I wonder if you ever thought about; what would it be like to print money? That'd be interesting. Wouldn't it? An unlimited amount of money! Well, I can tell you how to print some money today, and I also can tell you; how you can do that by using our invert-a-bolt fasteners™ and using our workholding products to improve your lean workholding manufacturing.

So, just recently I went to show this fixture to a prospective client. By the way, I like showing this stuff off, I'm extremely proud of our solutions in the CNC workholding marketplace. But anyway, I had a prospect with me, and he looked at this fixture and he was like, “Whoa. that's a lot of fasteners a lot of money there.” And, my response was, ” Well that is true. But, you don't have to spend that much money to get this result.”

Because each and every one of these fasteners can be leveraged to do exactly what you want so the cost of that single fastener isn't as bad as you might think.

For example: in a workholding fixture plate like this, we can plug the hole or you know we could have plugs everywhere here, and thankfully you can move these Invert-a-Bolt Fasteners™ around on that plate and that allows you to only use it where you need it.

In the same way, our Zipbushing™ has its own little plastic plug that we can use. So, we put those in there and then we just move our products around.

So, that you can do the job but at a much lower cost.

Now, when we think about eliminating waste, for example: In our the stream of production - this is one great way to do that.

So, here we don't do that.

We use a picture framing concept, in which you don't have to change clamps and you don't have these issues that come up when you're talking about the lean manufacturing methodologies.

We want to work with small batches, this is ideal for that kind of thing. We want to improve your throughput, that's what we call, ‘cycle-time’. For sure, you can do it.

So, the point is that we have ways that you can achieve these objectives without spending a ton of money.

Another thing that I wanted to mention to you is that: you could set up a fixture like this or even use the T-slot on your machine and get that benefit as well.

So, here's your T-Slot Fastener - slides in the slot to wherever you want it to go. You know it's infinitely variable, in essence, and so you don't even have the cost of the plate. You just have the cost of the fastener. Very, very low-cost solution to quick changing your vices and your other tooling, whatever you

got really.

Anyway, thank you for spending time with me.

We'll talk to you next time

-Rick Miller

CEO & Founder of Elijah Tooling

P.S. "Lean manufacturing, or lean production, is a production method derived from Toyota's 1930 operating model "The Toyota Way". Lean manufacturing is a methodology that focuses on minimizing waste within manufacturing systems while simultaneously maximizing productivity.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.