Hey guys, it's Rick from Elijah Tooling. Normally I say give me two minutes, but I won't lie to you, it's going to take a little longer than that. But I'll put my fingers up anyway, how's that?

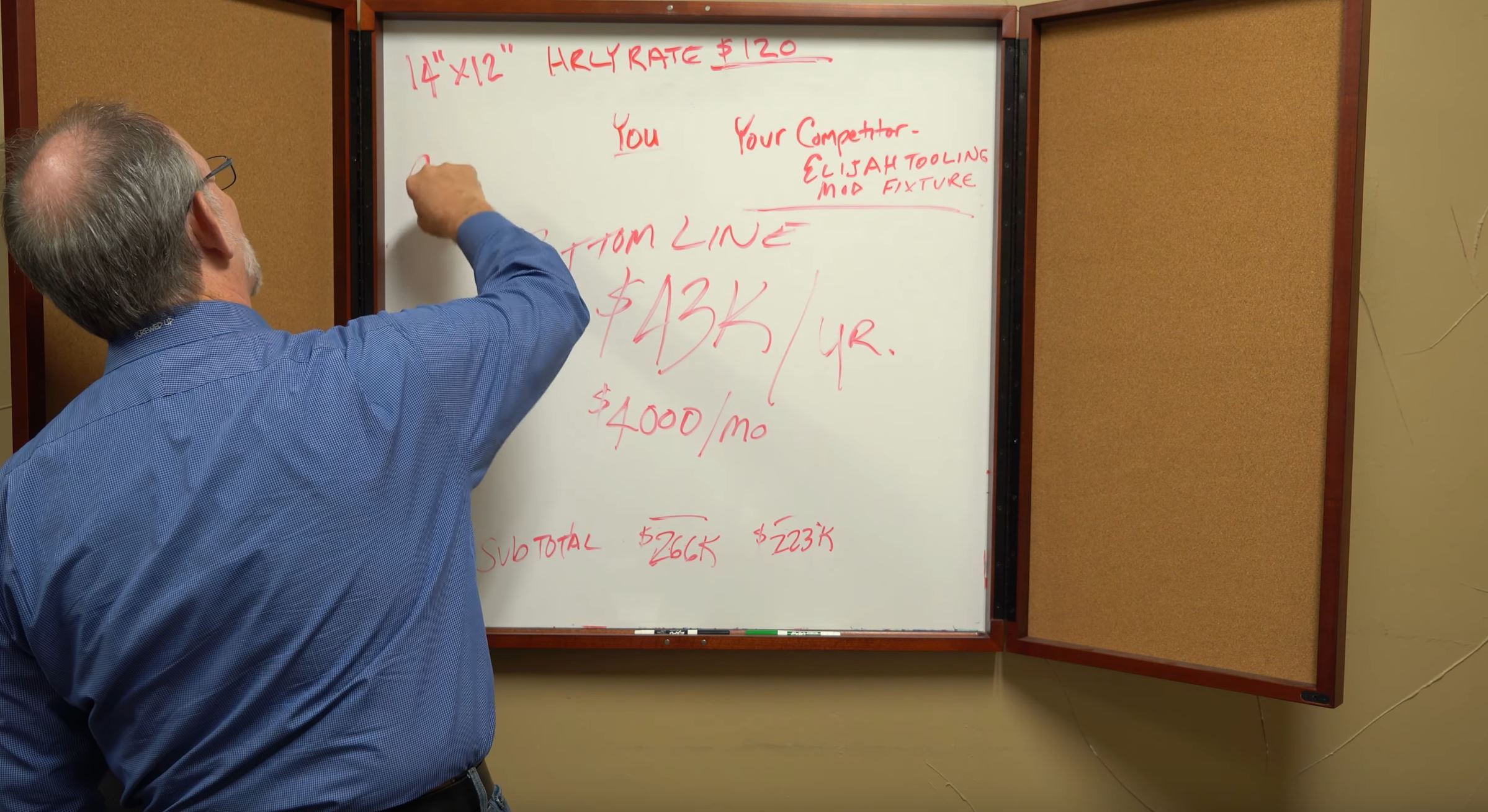

Alright. Today I want to show you something kinda cool. Because it's going to show you the difference between clamps and our workholding fasteners. So, we have workholding clamps on a CNC machine, and we got our workholding fasteners which you can see on this table.

So let me just, this is going to be fast, kinda. I'm going to time myself in using the clamps on and off, using the fasteners on and off. Okay? You with me?

Alright, here we go. Here is our super-duper part and we want it to sit right there. So, let's start the clock, you see it? Can you see the clock?

So, then I got to put the rest on the clamp, I got to get the clamp on there. So, of course, I had all this set up beforehand. The thing that's nice about the workholding fasteners, is that they are always in the same place. But nonetheless, we are going to give it the benefit of the doubt for the clamps, okay?

Let's get this on here like that. Alright. Alright, cool. I got... hold on, 48 seconds. Somewhere around there. Okay. Now we are going to take them off. I'm going to keep the camera going so that we see the whole sequence, okay.

Alright, let's assume we're going to load the same part again so we'll put this back on here. We'll this is kind of a pain. That's what I am saying. Alright, here we go.

Okay. Alright, there you go. The whole sequence, more than a minute because I kind of messed up. But, we'll leave it.

Alright, let's see what happens with the fasteners now. So regular gooseneck clamps right. Alright, cool. Like I said fasteners are always in the same place in our modular fixture. So. We don't have to worry about them being there, they're always there. We don't have to worry about finding them, getting them up.

Okay, hold on. Let's start this thing, alright. There you go, hold on. 21 seconds. Alright, now we're going to release the part. And we keep going here. Alright. Ta da, 35 seconds. Now let me tell you something else that is important when we're talking about comparing workholding fasteners to these clamps. So when we have a clamp and it sits up here like this, right?

All you're forces are up here, which allows your part to have more vibration. It's less stable, the thing about the forces that we are applying, we're applying them right here at the base plate.

Where the base plate is taking the load. So, what happens is; when you use one of our invertabolt fasteners you have an extremely stable set up. And that primarily why you see it used in high-speed machine; where it's very important that the set up is very stable. Anyway, you got it. Here we go, see you later.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.