Hey, guy's it's Rick at Elijah Tooling. Give me two minutes, at least two minutes, and I'll make it worth your time.

So today, I would like to present a thought to you that just came to me. Which I found is a terrifying thought, in a sense, terrifying. And that is, what if you are competing against somebody that's using our products. Elijah Tooling products. You're not using them, they are using them.

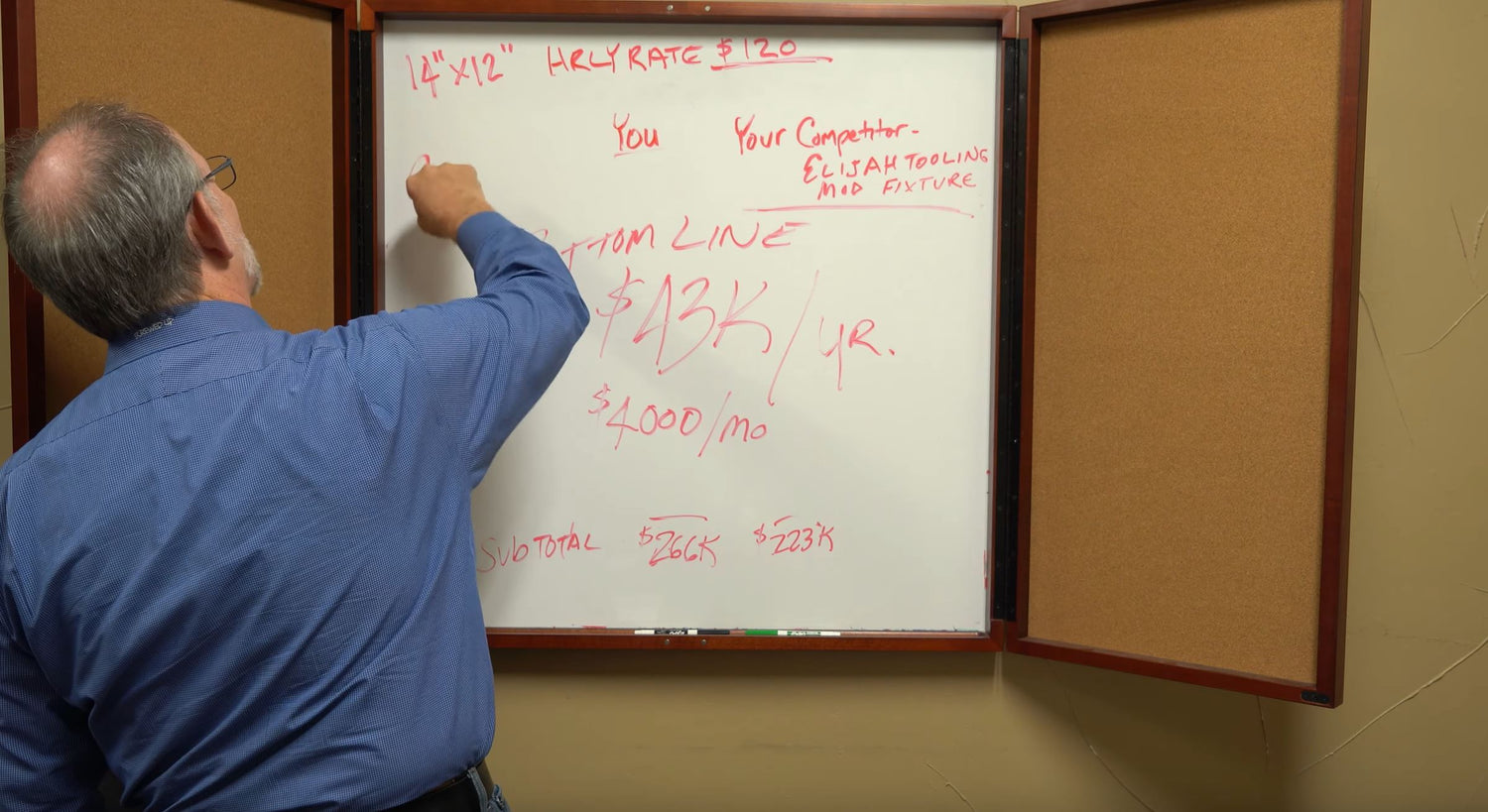

What's that look like? What is the downside for you? Or, the potential upside for you? From a financial standpoint. So I thought you know what, I'm gonna put it down I'm gonna put it in a spreadsheet. Now, this isn't a spreadsheet, but the numbers went into a spreadsheet, and when we get to the bottom, you'll see the answer to the question. But the question really is, "does it make financial sense to use an Elijah modular fixture, versus dedicated tooling, clamps and that kind of thing. So let's take a look, we've got this all set up already.

We've made some assumptions so just to clarify these assumptions may not be exactly what you're gonna be using, but we had to start somewhere, and so where we started is we've got a 14" by 12" aluminum part, your hourly rate is 120 dollars an hour, I don't know whether that's good or bad, we might be higher, you might be lower, again you probably want to do this kind of thing yourself. But, it would absolutely make sense for you to do this kind of analysis. But anyway, let's just go through it and see what we got okay.

So I've written dedicated here, and this really applies to you, not to your competitor, your competitor is using a modular fixture, our modular fixture, okay. We'll stick to just our products for now.

So let's see what would one of our modular fixtures, well I'm gonna think of a big number okay so I'm gonna give it 15,000. Man, that sounds like a lot of money, and your fixture you've got a dedicated fixture, but yours is only 1,000, okay? Admittedly you know this might not be the right price, this might not be the right price, but at least in your mind, I'll bet you that your fixture is a lot less expensive than ours, okay. so that's where we're starting. That's the premise that we're working with.

So now, we're going to go down through the steps of actually changing the fixture on and off. In other words, changing the parts on and off the machine, and so forth. I've also made the assumption that we're going to make 16 parts a day. So the machining of this part is roughly 40 minutes or something like that. I think so in an eight-hour day, right?

So, changing out the fixture, so we've got to clean the fixture, got to go get the fixture, actually. But we got to clean it, we got a stone the table might have to stone the fixture, and then we're going to load it onto the t-slot table, we're gonna indicate it in, and then it's going to be ready to go. Well, how long does that take? Well, we're estimating it at 60 minutes. The thing is, I think that's a REALLY CONSERVATIVE NUMBER. But, you can easily go figure that out yourself. I'm sorry, I put that in the wrong column. 60 minutes, that's you. The Modular fixture, already on the machine, never gets changed.

So what is it? Zero. Alright, so now we're going to take and load some stock material onto the fixture. What does it take to load it, indicate it in, and clamp it down? Well, we're giving it a very conservative 10 minutes to do that. And for ours, all you're doing is zipping the stud of the fastener up into your part. However, many times you've got, however many times you use them. So we're gonna say it's 5 minutes, okay. Pretty realistic, by the way. That's pretty realistic for this size part. Remember, this is our assumption.

We're not talking about an 8 foot by 12 foot part, or something like that. Alright, now we're going to go to stage 2. What does it take to change clamps? Alright, we're going to 10 minutes again. Again, these are very conservative numbers. And we're going to give ourselves 5 minutes. Stage 2. Now, we've gotta remove the part once it's machined, right? And in this case, because that part has been picture framed, you are going to have to break the tabs and do some hammering.

So we're going to give that a 10-minute time frame. In your case, you're gonna remove the part, and I'm going to assume that it's net. When you take it off. So, 10 minutes. Alright? Now in our case, you have to prep the material for the fasteners, and let's just say we got 10 fasteners that or being actively in use. 10 minutes. you don't have to prep, right? You're not prepping for fasteners. So there are our numbers.

Now, I'm going to erase the board, and we're going to come up with what's the bottom line, because that's always what it's about, Right? Bottom line, alright? Okay, I'm back, and I got it all erased. Now, we're going to talk about the bottom line cost. Don't you like the bottom line? I do. I want to know, "what does it end up being?" I'm so excited, this is really cool!

So, let's take a look at it. Our capital expense daily, for the modular fixture, is $58. That's what it costs for that $15000 Modular Fixture. Remember, it's a $15,000 cost, right? What is your cost? Well, you're gonna be spending $200 a day. That's if you're switching out a dedicated fixture, once a week, that cost a $1,000. Put your own numbers in there, but $200 is what we're starting with here.

So, your yearly costs for those fixtures is $52,000. You can see this is kind of a big deal right there, right? So, interestingly enough, we had the same number of minutes for fasteners and clamps. Honestly, I think that we're being very conservative with the clamps, and I think that we're being hard on the Invert-a-bolt Fasteners.

But, we're gonna leave it alone. So daily, I've got an approximate number of $800. Exactly the same, alright? The cost of the fixture, changing out weekly: So, in our case, this is you, did we get this, I did this again, I got these backward guys. Let's change this up a little bit, not sure why I keep doing that. It's $58, and $200. Sorry about that, I'm just human here. $52,000 and $15,000, okay.

I just wanted to scribble on the board more. Anyway, the cost of the fixture change out, weekly, we don't have a cost for the modular fixture. It lives on the machine. That's it's home. In your case, you're switching out these thousand-dollar fixtures, and we said that it would take 60 minutes per change out. Only once a week and we got a cost sixty to forty.

So again, I think these numbers, if you do your numbers, you're going to come out a lot better than I am, in favor of our products. But nonetheless, we don't want to pull the wool over anybody's eyes. We just want you to look at it objectively. If you do that, I think that you'll be calling us.

Anyway, we have a recurring cost yearly. I got to look this number up. So, we're at $208,000. Okay, added all this stuff up. And, we got a subtotal of $223,000+ and $266,000+. Whoops, did it again. Did it again. $266,000 that wouldn't be a perfect sales pitch if it was the reverse, right?

Okay. $266,000+, and $223,000+, so what is the bottom line? What is this all about? Well.... oh and by the way your guys are gonna like using the fasteners a lot more than clamps, there are some intangibles there.

But, nonetheless, bottom line: We are going to save, bottom line... 43,000+ a year that's roughly $4,000+ a month. $4,000+ a month. That's for one machine. Multiply it by all of your machines, and pretty soon you're talking real money. So this is why our customers buy this product. This is what it's all about. They did the math.

So, what's the ROI on this? Well, ROI on that $15,000 fixture, that we all thought was really super expensive in the beginning, only took four months. So, next time you're buying capital equipment, find out what you can get paid off in four months. And by the way, I think that again our numbers are extremely conservative.

Anyways thank you for spending time with me. I hope this has been enlightening. I'm excited about it. Hey, see you later!

Marketing and video production by The Uptown Agency. www.theuptownagency.com

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.