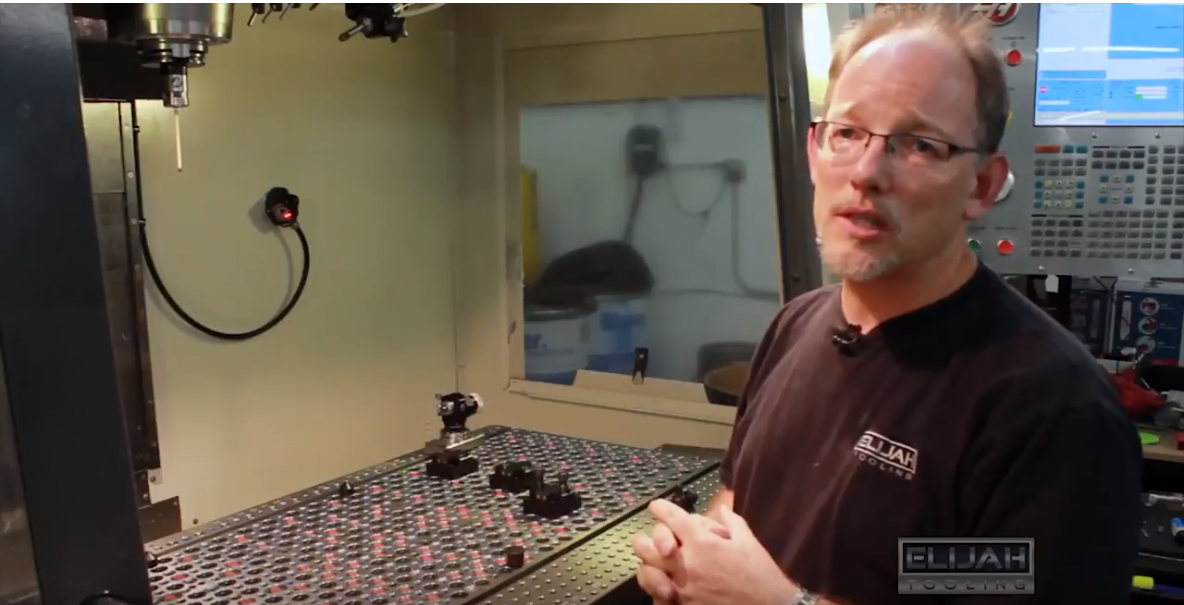

Hey guys, Rick here from Elijah Tooling.

I wanted to introduce you to some of our products; I am going to start with the Invert-A-Bolt™ Fasteners. This is our claim to fame. This is a patented product, it is very simple and, as you can see, it is stainless steel.

Basically the way it operates is that it has an outer housing, it screws into the piece that is holding it. Normally, that is a fixture plate, but it could be anything. Then it has a little threaded portion that comes out the top and we call that the stud. So, the stud moves into the piece that is being held and it allows you to hold workholding material, whatever it may be without using clamps or bolts. So, we have got a number of these in different sizes but this is the most popular Invert-A-Bolt™ Fasteners. It is a half inch, we call it a 1/2" AA02 STYLE INVERT-A-BOLT™ FASTENERS

We have got another one just like it but it has shorter stick out, a shorter stud engagement. the stud engagement for the classic one is 0.45 inches and for this one it is 0.3 inches. And I am going to demonstrate the use of these products in just a minute but I am just explaining each one of them briefly. So, another thing that is nice about these is that we have got them in two different housing sizes. This is the AA02 type housing where it houses either a half inch stud or a three eighths stud and then we have the smallest version that houses five sixteenths.

So, if you are using these in a modular plate like this, you can swap out these Invert-A-Bolt™ Fasteners to go to a different size if you need it. And, it works the same way with this larger housing, the AA03 STYLE INVERT-A-BOLT™ FASTENER, which is another popular one and has a half inch stud as well. This is common with two different sizes, it has a half inch and then we have a five eighths housed in the AA03 type. It has a one and a quarter inch outer diameter and the AA02 have a one inch outer diameter.

And then we have some new products which are, basically, the same thing except for that they are common with our precision locators because of their height.

Thank you for your time.

-Rick

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.