Understanding the "Picture Frame" Method

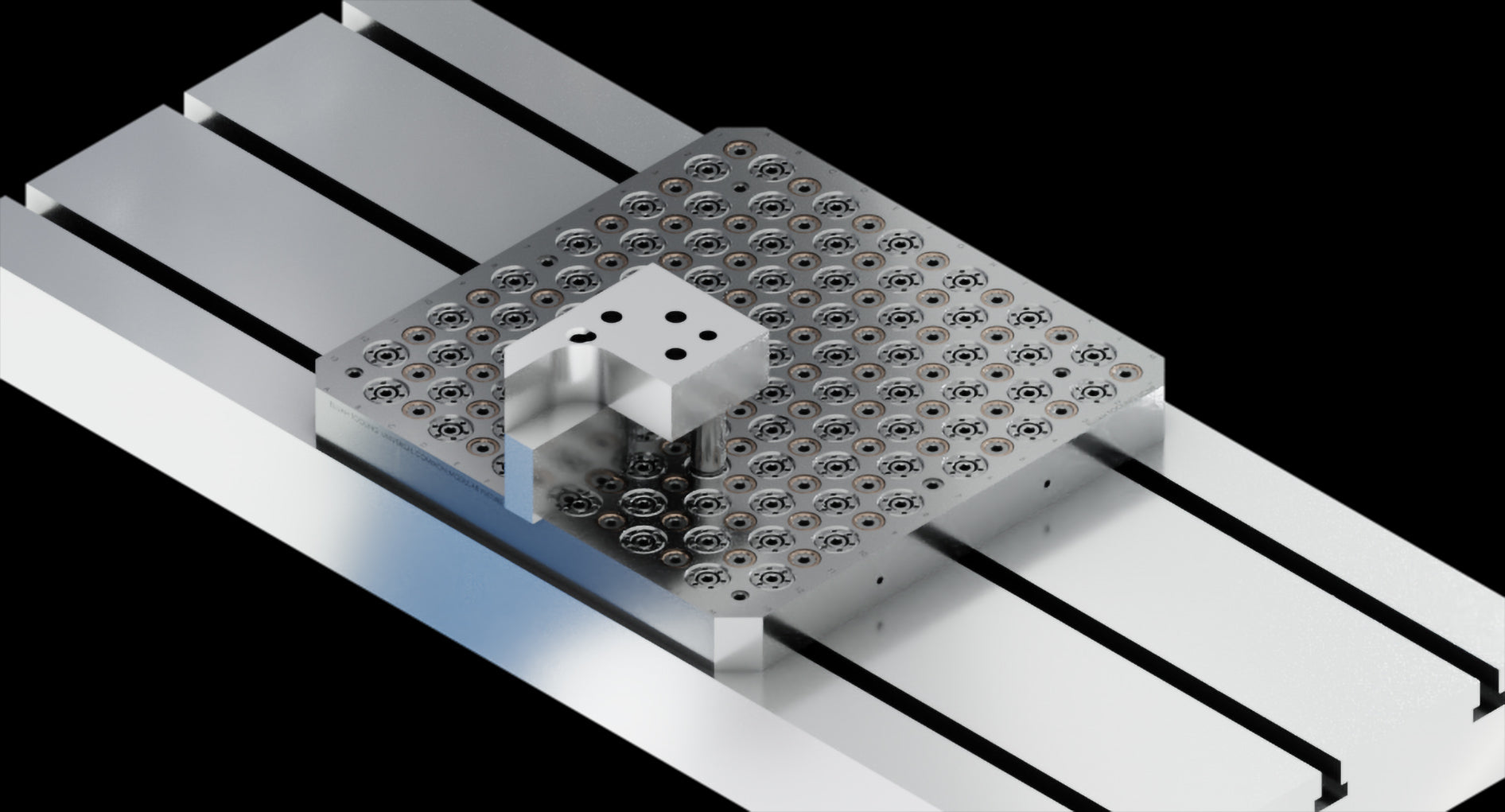

The "picture frame" method is a CNC machining technique that involves securing workpieces using a series of fasteners around the perimeter, much like a picture frame. This approach provides several advantages, including exceptional workpiece stability and rapid setup changes, making it a valuable asset for machinists across various industries.

Why It's Called the "Picture Frame" Method

The name derives from the way workpieces are clamped, similar to how a picture frame holds a photo or artwork in place. Instead of clamping a workpiece directly at its center, you use a series of clamps or fasteners around the edges, providing stability and precision, just like the border of a picture frame.

Leveraging Invert-a-Bolts

Invert-a-Bolts are pivotal in the "picture frame" method. These versatile workholding solutions come in different sizes and are designed for easy integration into various CNC setups. Invert-a-Bolts allow you to quickly secure workpieces by locating them from the bottom, making it a perfect fit for the "picture frame" technique.

How Invert-a-Bolts Work

Invert-a-Bolts are essentially fasteners that are installed from below the fixture plate. They can be easily adjusted and secured, ensuring the workpiece remains firmly in place during machining. The advantage of Invert-a-Bolts is their compatibility with the "picture frame" method. They enable you to clamp workpieces along their edges while maintaining stability and precision.

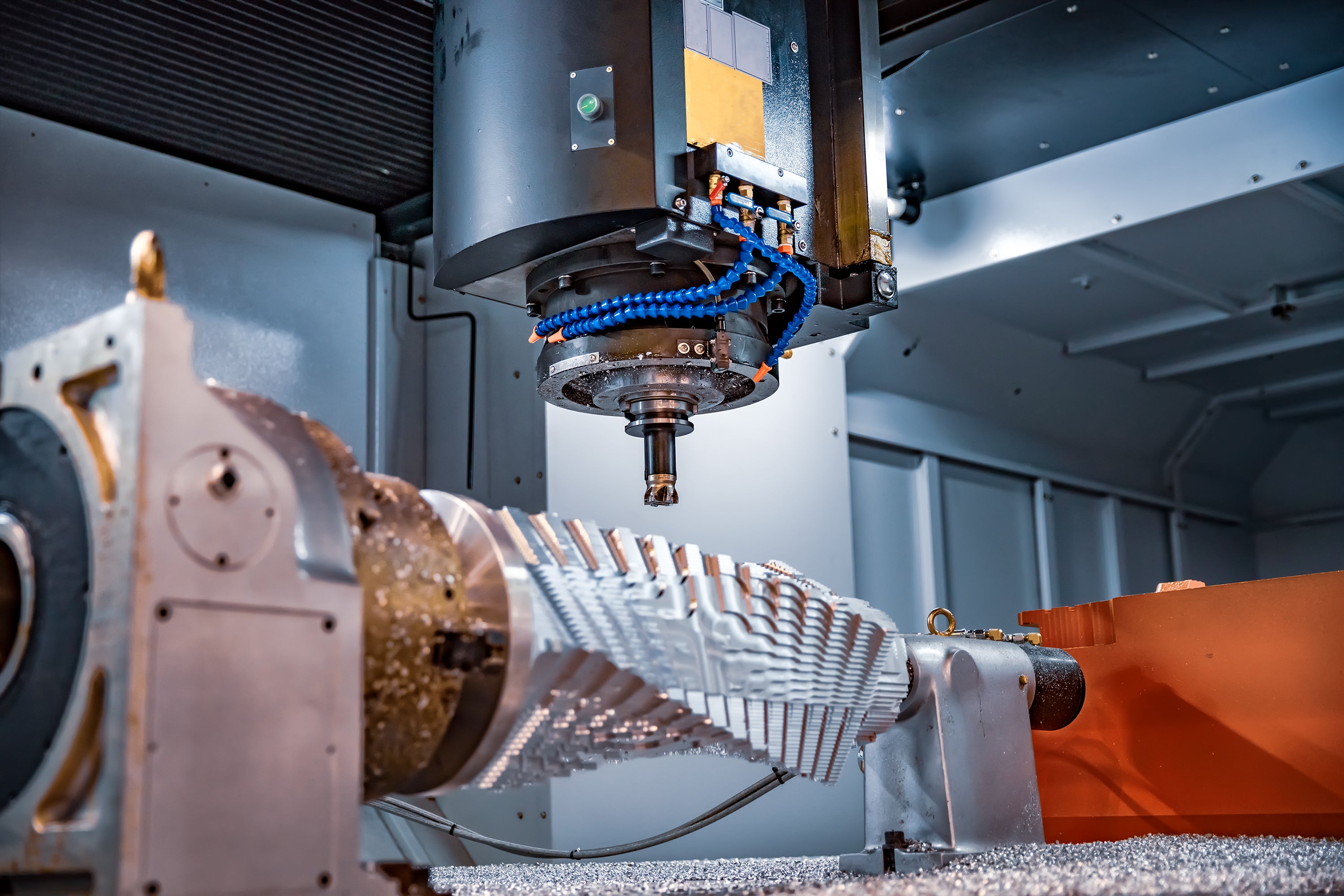

Applications in CNC Machining

The "picture frame" method has wide-ranging applications in CNC machining, including:

- Machining Large and Odd-Shaped Parts: It's particularly useful for workpieces that are too large or have irregular shapes that don't fit well with traditional clamping methods.

- Batch Production: When you're working with multiple similar workpieces, setting up a "picture frame" fixture can streamline the machining process by reducing changeover times.

- Reducing Material Waste: By clamping workpieces only around the edges, you minimize waste since there's no need for excessive material removal.

- Enhancing Precision: The method's stability ensures the utmost precision during machining, resulting in high-quality finished products.

Evidence and Success Stories

The "picture frame" method, when coupled with Invert-a-Bolts, has garnered significant attention and success in the CNC machining community. Machinists have shared their experiences and results, showcasing the improved efficiency and precision achieved through this innovative approach.

- In a review from Bruce at Focus: Hope Manufacturing, he describes his experience. "... The first Invert-a-Bolts have been used and the personnel on the floor love them. The numbers have already sold the big cheese. Our efficiency [on this job] went from 47 to 89 percent the moment we installed the invert a bolts..."

- This YouTube video demonstrates the quick setup achieved with Invert-a-Bolts.

- Forum discussions such as this one show first hand what it's like using the Invert-a-Bolt and picture framing method together. "The beauty of the Invert-A-Bolt we found at Cessna is that you can make a universal type fixture and run many, many parts over the same tool. In fact, 90% of the dedicated tools at Cessna were eliminated with this concept. Granted, you need to tab or picture frame your part, but that is a small cost compared to the savings in tooling, storage, maintenance and retrieval, plus, your bolts are ALWAYS right there."

In conclusion, the "picture frame" method, combined with Invert-a-Bolts, is transforming CNC machining by enhancing precision, efficiency, and versatility. As evidenced by real-world success stories and case studies, this innovative approach is gaining momentum as a game-changer in the CNC machining industry. Whether you're a seasoned machinist or new to the field, exploring the "picture frame" method could lead to significant improvements in your machining processes.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.