Machinists play a critical role in the manufacturing industry, and their skills directly impact efficiency and productivity. To stay competitive in today's fast-paced manufacturing landscape, machinists need to continually improve their efficiency. In this article, we'll explore evidence-based strategies that can help machinists enhance their machining processes and optimize productivity.

1. Tool Selection and Optimization

Selecting the right cutting tools and optimizing their usage is paramount to machining efficiency. Research from the Informatica Journal¹ suggests that selecting cutting tools based on factors such as material type, tool geometry, and wear resistance significantly impacts machining performance. By choosing the right tools, machinists can reduce tool wear, improve surface finish, and minimize the need for tool changes, resulting in time and cost savings.

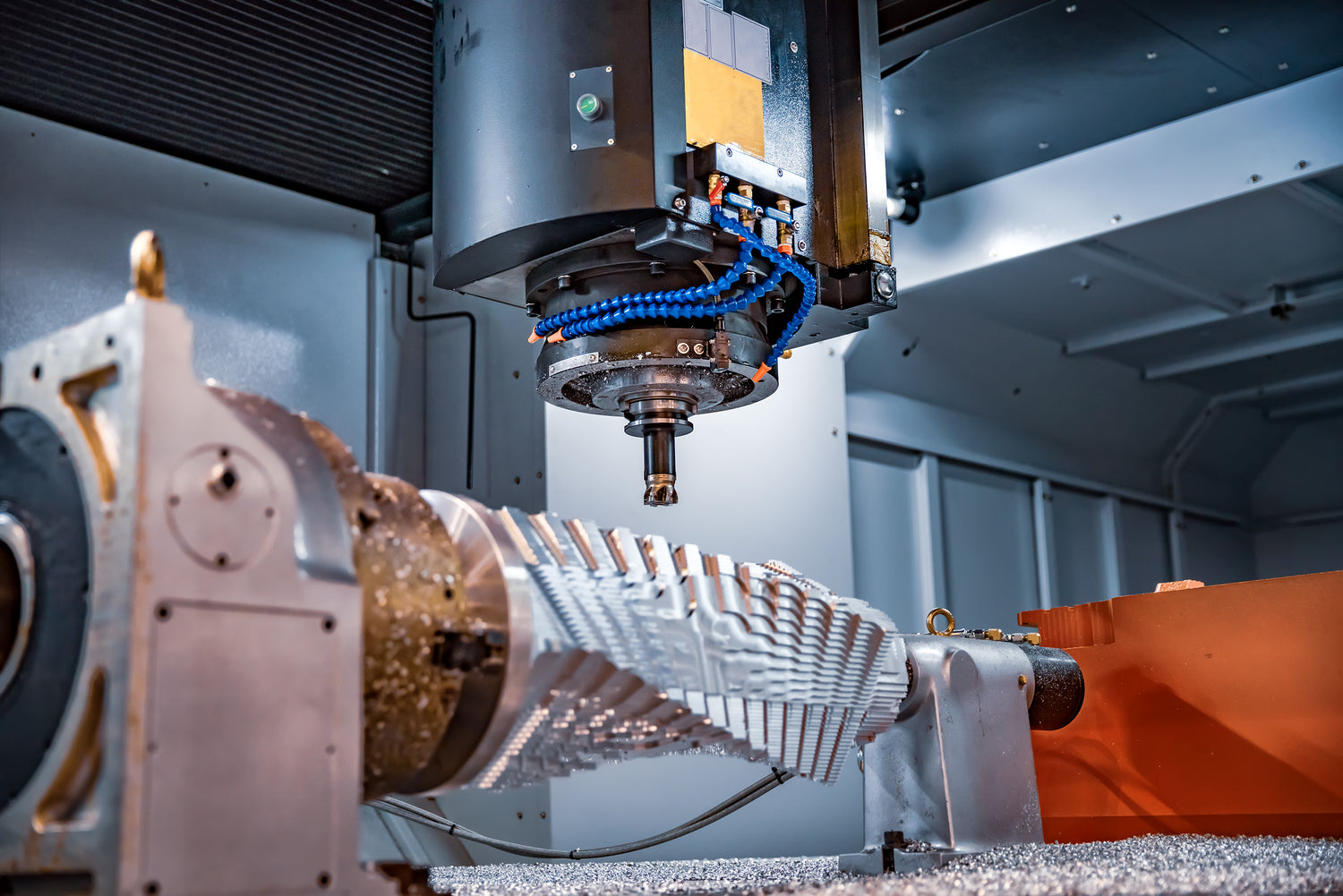

2. High-Speed Machining (HSM)

High-speed machining is a well-researched technique known for its ability to boost machining efficiency. A study published in Procedia Engineering² demonstrates that HSM can increase cutting speeds, reduce cycle times, and enhance surface quality. Machinists can explore HSM strategies to optimize their machining processes for faster and more efficient production.

3. Advanced Toolpath Strategies

Utilizing advanced toolpath strategies can significantly enhance machining efficiency. Research from the G. Kiswanto and Yolanda Rudy Johan³ reveals that adaptive toolpath strategies, such as trochoidal milling, can reduce cutting forces, improve tool life, and reduce machining time. Investigating and implementing these strategies can lead to substantial time and cost savings.

4. Cutting Fluids and Lubrication

Proper application of cutting fluids and lubrication is another evidence-based method for improving machining efficiency. A study in the International Journal of Precision Engineering and Manufacturing⁴ suggests that the use of cutting fluids can reduce tool wear, control heat generation, and improve surface finish. Machinists should pay attention to the right choice and application of cutting fluids to optimize their machining processes.

5. CNC Programming and Simulation

Computer Numerical Control (CNC) programming and simulation tools are essential for optimizing machining processes. Evidence from ScienceDirect⁵ highlights the importance of CNC programming in reducing cycle times and ensuring precise machining. Machinists should embrace advanced CNC programming and simulation tools to streamline operations.

6. Workholding Solutions

Effective workholding solutions are crucial for machining efficiency. Research from SME⁶ suggests that modern workholding solutions, such as quick-change fixtures, can reduce setup times and enhance productivity. Machinists should explore innovative workholding solutions to minimize non-cutting time.

Improving machining efficiency is essential for staying competitive in the manufacturing industry. Evidence-based strategies, such as tool selection and optimization, high-speed machining, advanced toolpath strategies, proper cutting fluids, CNC programming, and innovative workholding solutions, can significantly enhance productivity and reduce costs. Machinists who embrace these evidence-based approaches can expect to see tangible improvements in their machining processes.

By continually seeking ways to optimize their practices and staying informed about the latest research findings and technological advancements, machinists can remain at the forefront of the ever-evolving manufacturing landscape.

1: https://content.iospress.com/articles/informatica/infor461

2: https://www.researchgate.net/publication/261104049_Experimental_Study_on_the_High_Speed_Machining_of_Hardened_Steel

3: https://www.researchgate.net/publication/329186440_Toolpath_strategies_and_management_to_optimize_energy_consumption_on_3-axis_CNC_milling_machine

4: https://www.researchgate.net/publication/280567408_STUDY_AND_ANALYSIS_OF_NATURAL_OIL_BASED_CUTTING_FLUIDS_USING_MINIMUM_QUANTITY_LUBRICATION_SYSTEM_FOR_ALLOY_STEEL

5: https://www.researchgate.net/publication/326537446_ACAM_A_CNC_Simulation_Software_for_Effective_Learning

6: https://www.sme.org/technologies/articles/2018/april/workholding-solutions-to-reduce-costs-increase-throughput/

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.