Hey guys, it's Rick at Elijah tooling. Give me two - I'll make it worth your while!

You ever had one of those cringe-worthy moments? I'll tell you, I had one. It's been a long time ago now, but I was out on a sales call and I was out in the shop, walking the shop, which so often I do. And the person I was with showed me the setup that they had. There was a long part on a vertical machine and it was being held with vices. And I mentioned that with the Invert-a-Bolt fasteners that the set up would be much more stable. Well, you know how it is with a salesman, he listened, but I don't know that he took it all in or it even registered.

So we got done with the shop tour, walked back to his office and "KABOOM"! I could hear it out in the shop - Something had crashed.

He ran out there and I waited around to see whether he'd come back and sure enough, he did. And he said, the part that we had been looking at had just been thrown off the machine; it had crashed. And I say, here's the cringe-worthy moment, I said "I told you so".

Now I'm sure that that wasn't well received. It was a really bad time to say something like that. And so I just slithered away, said my goodbyes and expected to never hear from him again. But what happened was, they became a customer and not just any old customer, but a long-term customer.

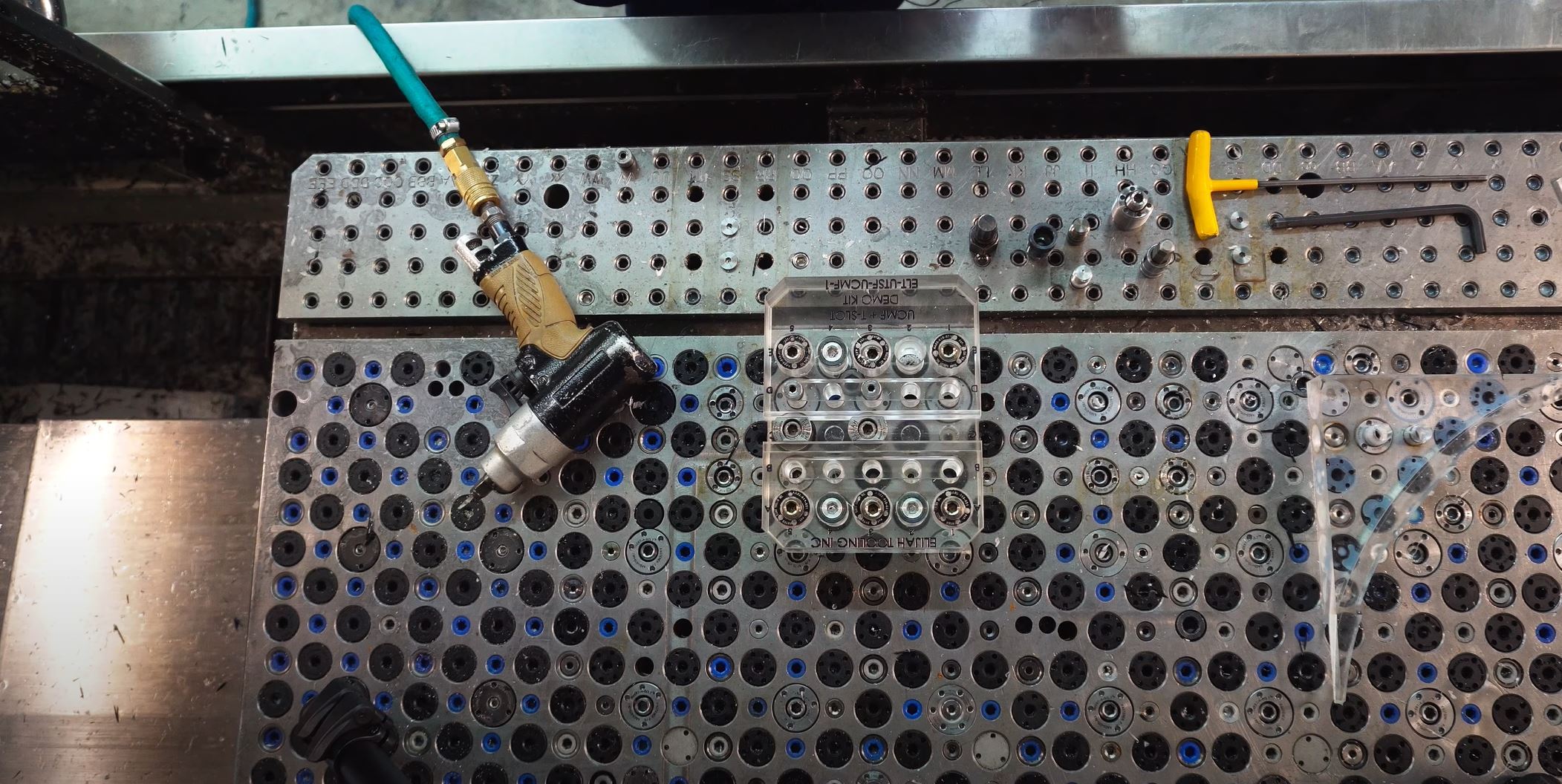

So I want to show you today, what the difference is. Right here we have a vise, like they were using. You're familiar with it and I'm not going to diss this vice; of course it has great value, but it's not perfect for every single situation.

Now let me tighten this up and I'm going to whack on it. If I whack on it, you can hear it actually; you can hear it moving, you can see it moving. Well that's what happened in their case.

Now let me show you what happens with the Invert-a-Bolt fastener. As you can see, there's a large plate here and you're going to have to take my word on that it's being held with our Invert-a-Bolt fasteners, but I'm going to show you with this little plastic plate, how it's held.

So you have to knock that down because a it's locating tight. All I'm going to do is bring the fastener up, which by the way, you can tell it's pretty fast. So the great thing about the Invert-a-Bolt fastener is that all of your forces are right at this plane. So the fastener doesn't stress the plate, but the fastener does create a very stable setup.

And in fact, we've had customers that told us that they could hold flatness and parallel parallelism where they couldn't before. And that's partially probably because they were stressing the part.

Also just for kicks, here is our T-slot fastener and as you can see, it runs down here and it goes in that hole. So just FYI, that's how those work, they work the same way.

Anyway, that's all I really got to say. I had a cringe-worthy moment that turned out well, but we had to understand the difference between this product and this product and when their best to be used for whatever application they're in. Thanks for spending time with me. I'll see you next time.

-Rick Miller

Founder & President of Elijah Tooling

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.