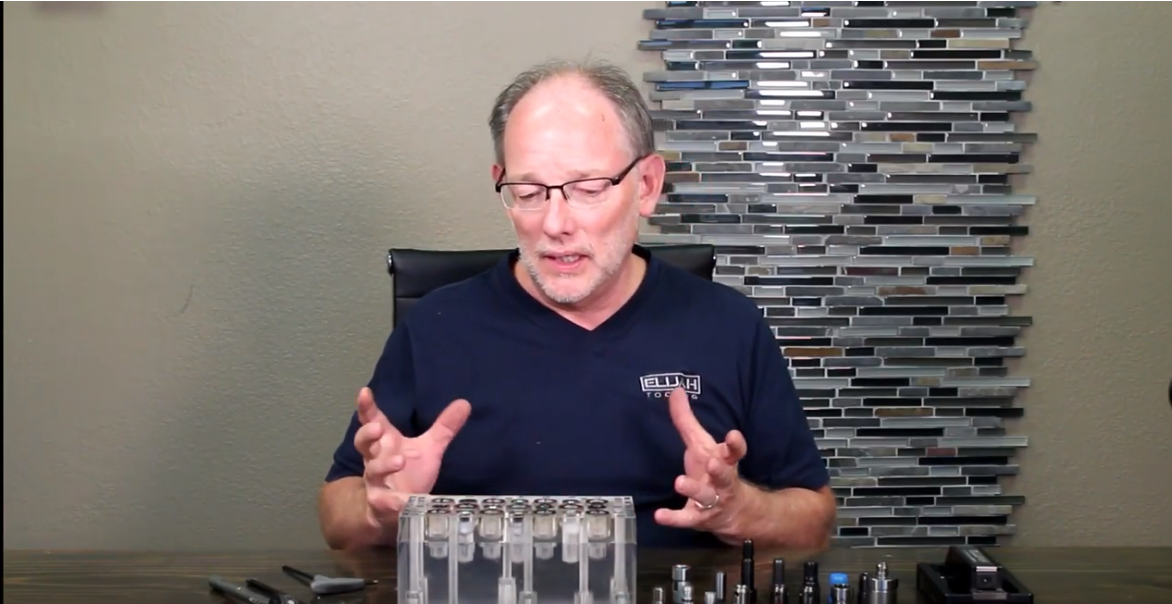

Hey guys, Rick here from Elijah Tooling.

I wanted to dig a little bit deeper into one of our products that we sell; our modular fixtures.

This modular fixtures is in an acrylic, see-through display. It has got a standard pattern; basically, it has got the Invert-A-Bolt™ Fasteners and it has also got a multi-purpose hole. That is a key feature of this fixture; the multi-purpose hole.

We used to do it a certain way; we used to take the threaded insert and screw it into a certain hole and then we would take the bushing and we would pound it into the hole and together, these guys made up what we call a multi-purpose hole. The benefit to that was that you could do a lot with it. This hole, basically, became the locating hole of our modular fixtures.

So, what we did was that we concepted and brought to market what we call Zipbushing™, an all-in-one, patent pending product that does the same thing as the previous two products do. It is driven by a ten-point driver so it can go in rapidly; it can be screwed in and out, with ease. It has a locating shoulder on the outside as well as on the inside just like a bushing and yet, it is driven like this.

So, I also wanted to go through some of the accessories of the product and let you know that there are some other options for it as well. For example, if you screw up a hole, and this is great as a replacement for these that already exist, you can go in with a larger step-up bushing. We actually have two sizes, one that goes beyond the previous one as well. So, you can screw it up twice and still have a good hole.

We also have an Aluminum Plug for 1/2" Zipbushing™ Multi-purpose Hole & Standard Multi-purpose Hole that goes into the zipbushing and that is primarily to keep material and debris out of the hole if you are not going to use it.

One of the key features of the Zipbushing™ is the use of the Xzertz™ Retractable Locating Dowel Pin that screws in and out the product. The idea here is that your locator is always in the modular plate. So, the Invert-A-Bolt™ Fasteners is always in the plate and your multi-purpose hole is always in the plate. You don't have to find it in a tool chest, it will always be in the plate.

I also wanted to mention that we have two different sizes; we have a f500 size and a 501. You do not want to mix those up. The 500 is a little tighter and the 501 is a little looser. That gives you some flexibility with regards to your locating products. We also have a 5/8 bushing called 5/8" EZE-Drive™ Zipbushing™ Precision Threaded Locator Bushing.

We also have a plastic insert here called Hole Plug for 1/2" EZE-Drive™ Zipbushing™ Precision Threaded Locator Bushing. It is made for when you want to move the zipbushings around. That is another key feature of this product.

Another product we have is a zipbushing that is made specifically as a receiver for our precision locators. Using this, you could rapidly create a hole that will receive that stud in the precision locator.

So, if you use the zipbushings with the Xzertz™ Retractable Dowel Pin, you can load your modular product rapidly; you just drop it onto the pins. What's cool about this is that if you have a plate and you are sliding it across your fixture, it is pretty convenient to pull or screw these fixtures up into the plate and we show that in some other applications.

Thank you for your time.

-Rick

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.