Hey guys, it's Rick from Elijah Tooling. Give me two, I'll make it worth your time.

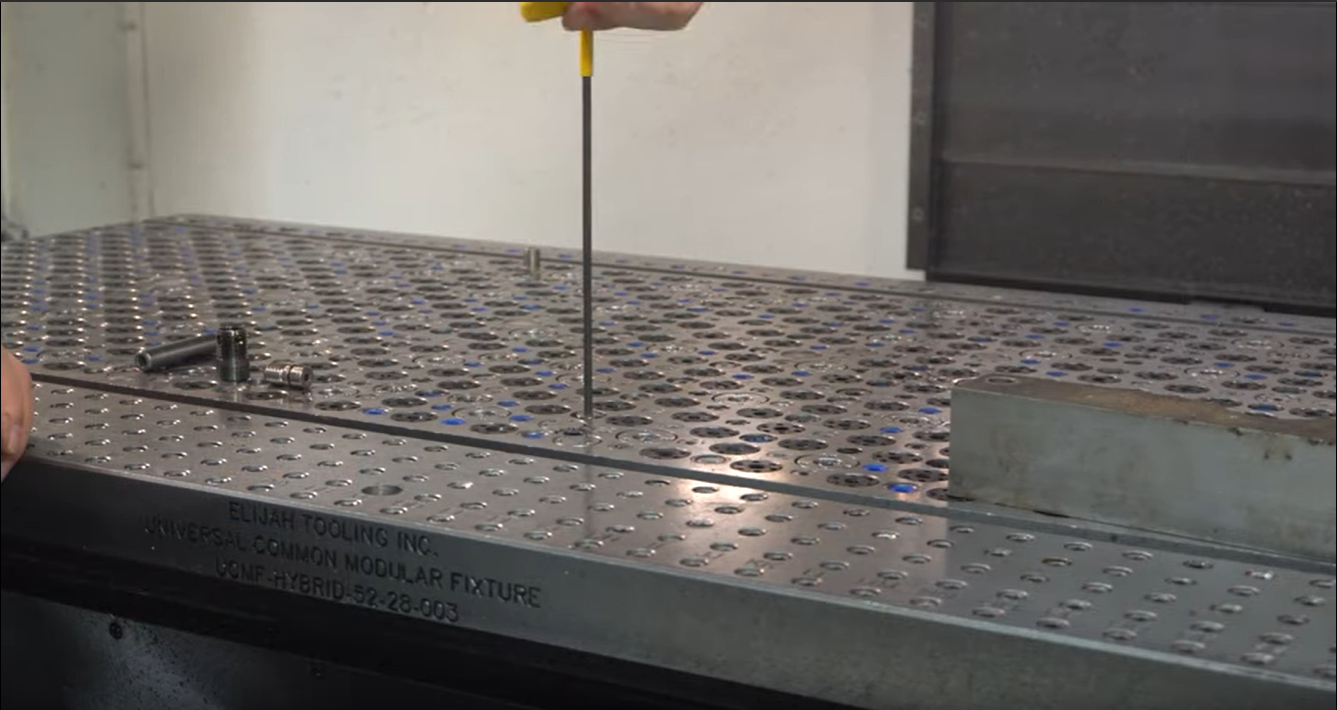

So, today I want to focus on this table.

I know we've done a lot of demonstrations over here on this machine, but I don't

know that we've ever talked specifically about this table.

But, one of the things I want you to notice: right here we've got these Xzertz™ here, and these pretty much show what the travel of this machine is.

A typical machine bag is the size of the table.

So, if we weren't using this oversized plate, it would be in this range right here.

Okay. I want to tell you a few things about why we went with an oversized table like this.

And I'm going to encourage you to consider that, because it can be a benefit to you in a lot of different ways.

So first of all, of course this is a modular fixture plate, I'm not

going to get into that.

We've got a lot of videos about how those work, what's

great about them.

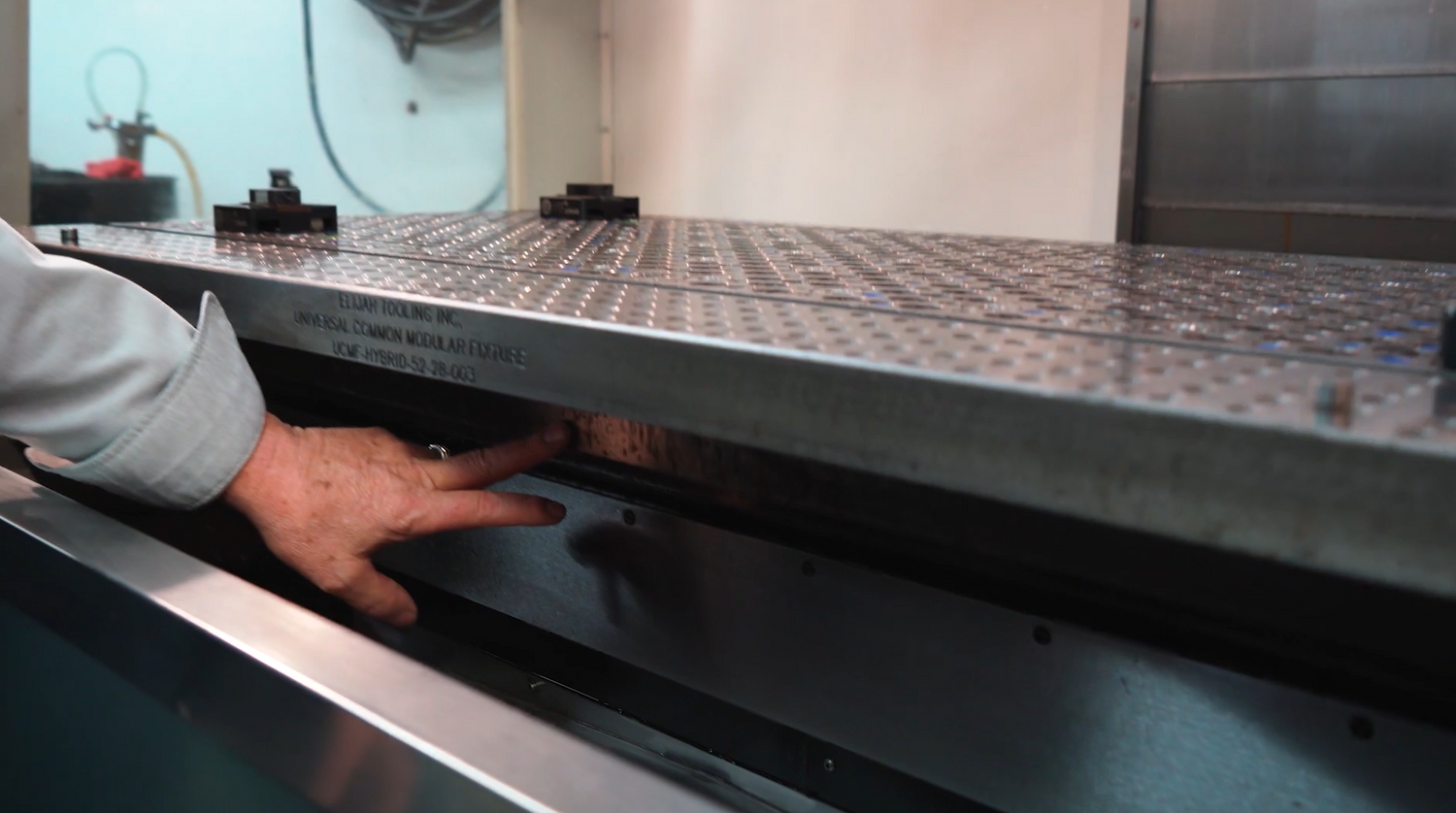

But, here's the deal: so if we look underneath here, we can see

here's the table.

The original machine table.

We've got about, oh I want to say six inches on the front of here.

And actually we could have come a little bit further if I was gonna make this plate again, we'd bring it out a little bit more.

And then, we have it about, I want to say, maybe six inches on both sides, okay.

So, what's the benefit?

Okay. Well, I put these vices here to kind of give you an idea.

One of the first or one of the most important benefits to it is simply that you're going to be able to use your travel, the entire travel.

You're going to be able to vice outside your travel, and then you're going to be able to machine the entire X&Y that you've got on the machine.

Have you ever considered that?

Why don't, why can't I make bigger parts?

Well, in this case: we've got the five-inch vice here, three-inch of vice here.

That's eight inches additional that you could machine in a x-axis.

In the Y. So, here's another cool thing about the Y: we're going to.

So, were going to go all the way back with this thing.

So, we didn't hit it right. And we actually have a little bit more space back there.

But, with the Y we can also adjust our table size to get more out of it.

But, there's another benefit.

Check it out.

So, if I've got something heavy and I'm the operator, normally I got to reach this much further to get over to the table, I've got to go "ohh", like that.

So the closer we can get this table to the operator, the more ergonomically positive this solution is.

So, I've got another feature that we can talk about.

So, what happens over on this end especially is that a lot of times you put a fourth axis type trunnion type device in here, and when you've got this extra room on the end, that it's not interfering with your travel.

Again you're making full use of the travel on the machine.

So, we've got three big features to consider a plate that's oversized.

One: we get more travel out of, or use of our travels.

Two: ergonometrics, making it easier for the machine operator.

And three: if we're using a fourth axis trunnion we're benefiting ourselves again from the travel standpoint.

Listen that's it. Thank you for spending time with me today, and we'll see you next time.

-Rick Miller

Elijah Tooling

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.